NATURAL GAS REDUCTION

Natural Gas Reduction

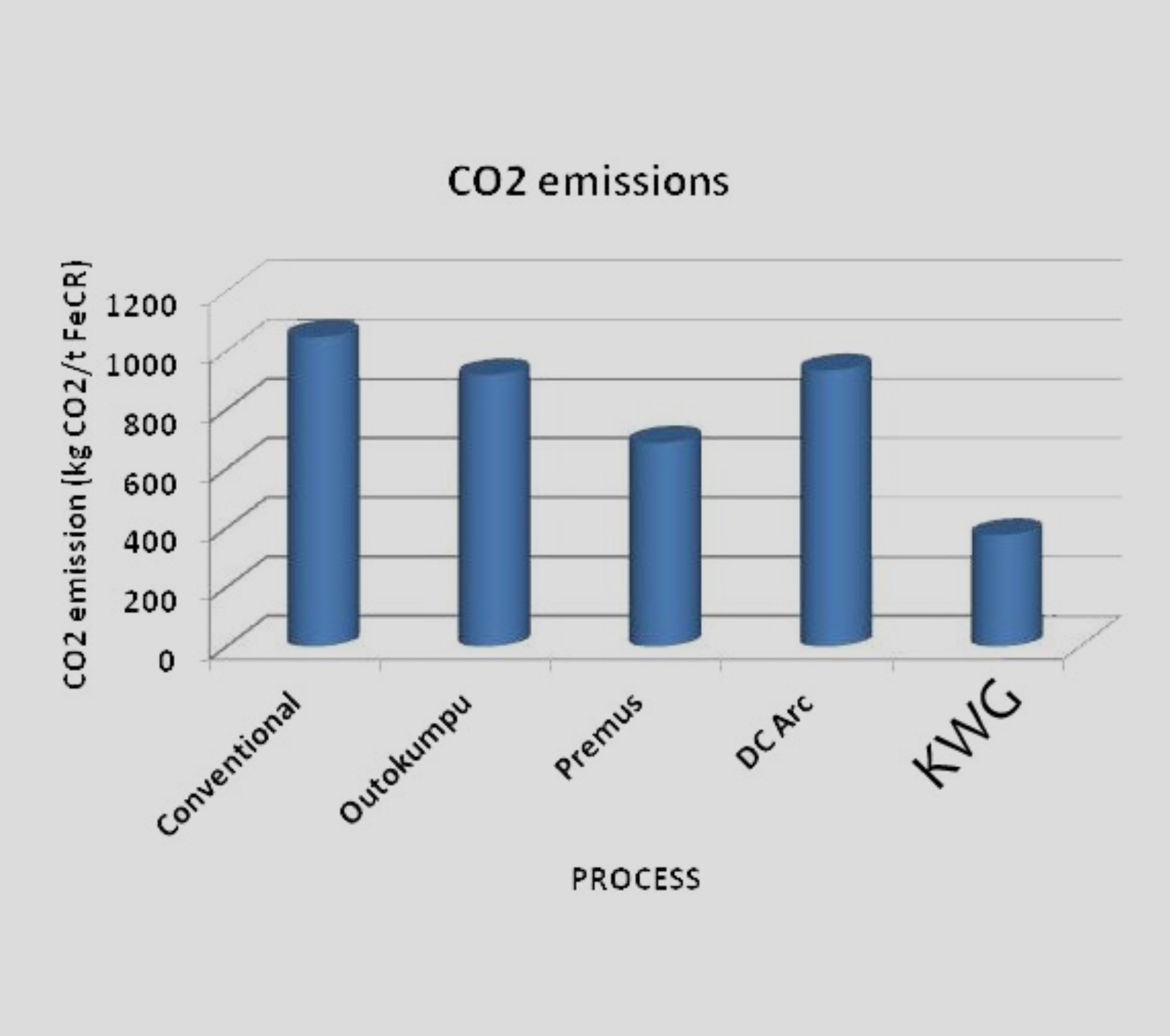

KWG Resources patented process to use a natural gas direct reduction to process the chromite ore will have enormous global competitive advantages in terms of reduced capital cost, reduced operating costs, and reduced greenhouse gas emissions. Using the direction reduction method, the need for the installation of a capital intensive smelting step is eliminated. Initial studies identify a reduction in overall energy consumption of 70% against conventional processing. By utilizing more natural gas than coal based energy sources, the KWG process is able to show an overall 50% reduction in greenhouse gas emissions compared with the most energy efficient current practice. The combinations of cheap and plentiful natural gas and large quantities of high grade chromite in Northern Ontario have the potential to completely revolutionize the market for chrome units in stainless steel manufacturing.